Making Things Last

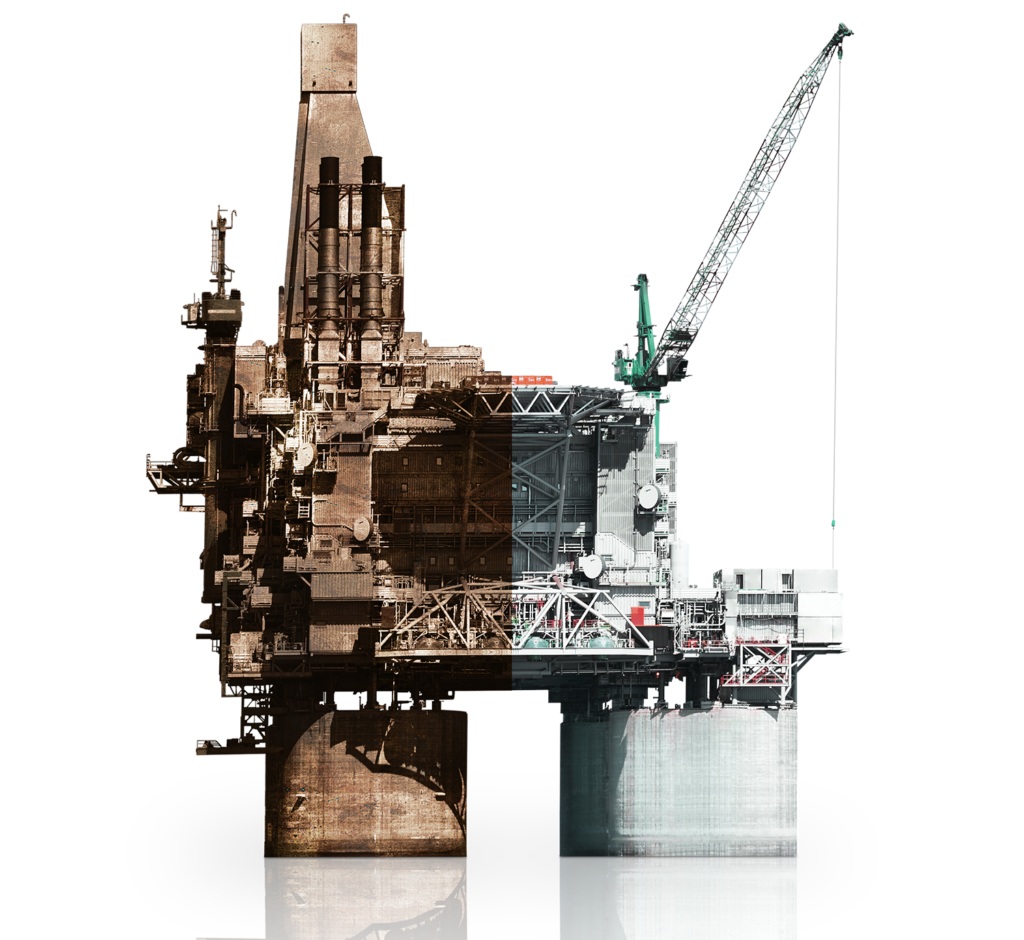

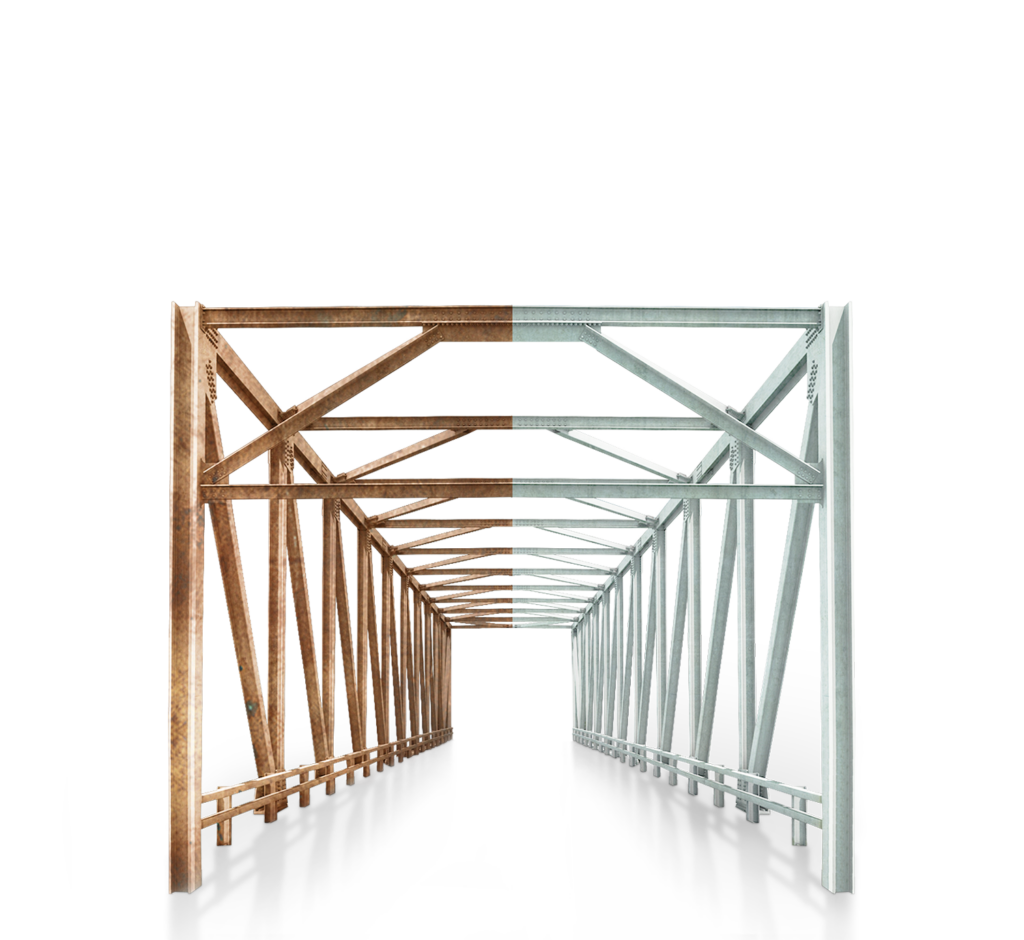

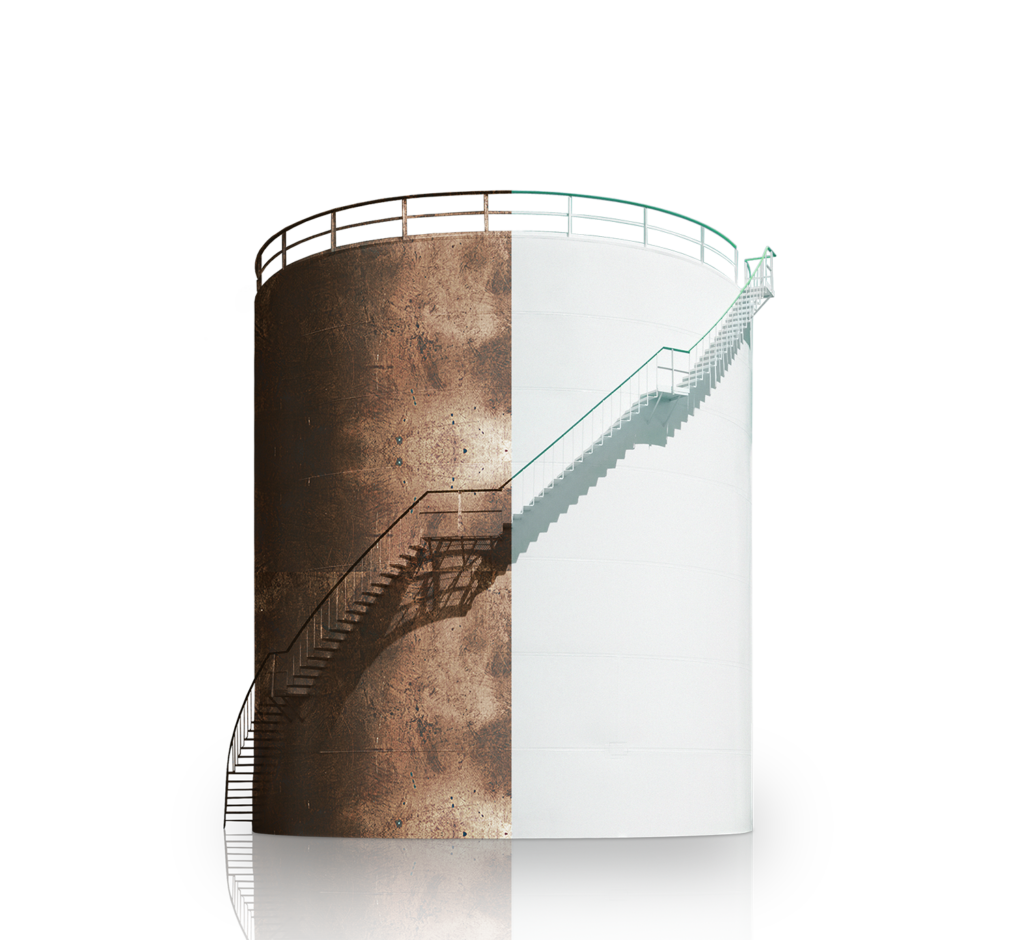

The Presserv Group is a leading preservation specialist offering customized protection and corrosion solutions within the energy, renewables and shipping industry.

Extending the lifetime of material assets is good for business, good for the globe.